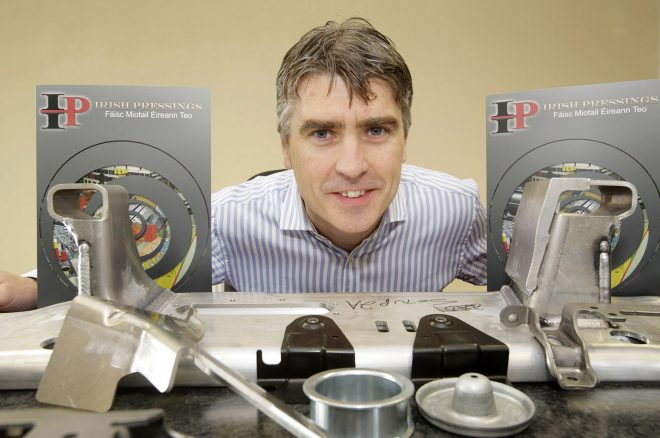

Declan Ward who set up Irish Pressings with his brother, Brendan. Today the company supplies to many of the top names in the motor industry. Photo: Paul McGuckin

Advertisement

WHAT links Posh and Becks, Harrison Ford, Simon Cowell, Conor McGregor and Queen Elizabeth II with Donegal?

They all drive cars containing components made by Irish Pressings based out of Gaoth Dobhair Business Park in Derrybeg.

Set up in 2005 by Kincasslagh brothers Declan and Brendan Ward, Irish Pressings is a proper old fashioned success story. From its early days with one, then two, then three staff, the company today employs 58 workers and is on the look out for more.

Irish Pressings survived and even thrived through the worst days of the recession, thanks largely to the talent and tenacity of its two owners.

Declan and Brendan Ward both developed their skills as toolmakers with Kirchhoff at its plant in Letterkenny.

“I was 17, just out of school, when I joined Kirchhoff and I was with them for about 16 years,” says Declan.

The Kincasslagh man worked across Europe, developing parts for some of the big names in the automotive industry. He was full-time Consulting Design Engineer on the Ford Focus, prototyping the car to tooling it to its assembly production. He was even involved in the establishment of satellite assembly plants close to Ford’s production facilities.

Following several years in Germany though he decided to return home to Donegal and start out on his own.

“After I came back from Germany we basically moved into an empty factory here in Gweedore. How it works with the industry is that you are pricing two or three years in advance and you have to achieve a certain standard first. So when we started out, our revenue was coming from making building products, things like joist hangers for local building providers.”

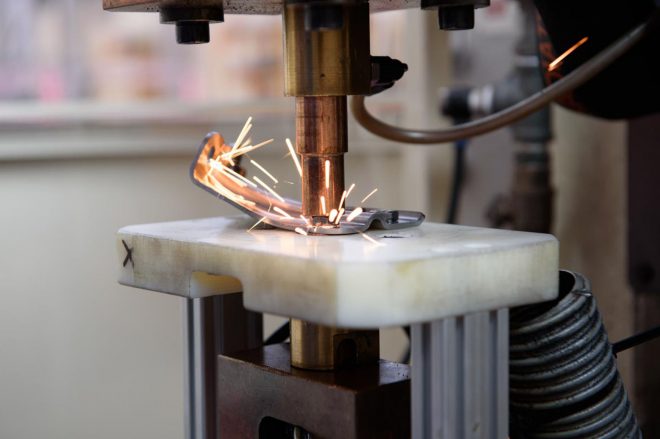

The next few years were spent pricing works and building contacts within the motor industry. And as trained toolmakers, tools being large pieces of industrial machinery, it made sense that they would build the equipment needed to create the car parts they intended to sell.

Making the parts that make the motors for the stars.

The next big challenge was to convince the motor industry’s big hitters that Irish Pressings could provide them with what they needed.

“When we started out we were deemed high risk because of our size,” explains Karen Campbell, one of the first Irish Pressings employees and now its Marketing Manager.

“Our potential customers were looking and going ‘but we have customers who have been in business for 40, 50, even 100 years’. But as the global recession hit, a lot of those companies went bust. We didn’t so they started looking back at us and realising that they might have to re-evaluate things. They came back, did an audit on us, looked at what systems and products we had in place and then placed an order,” Karen said.

Declan Ward adds, “We were still growing while others were going out of business. We had 25 or 30 per-cent growth while all these other firms were going bust. Through that and with Karen’s belief and her efforts to get our foot in the door, we got our break.

“ “We started with nothing. Even in 2008/09, we were still growing and we have worked our way up to the point where today we are competing with companies all over the world, some of them with hundreds or even thousands of employees.”

So why did Irish Pressings survive while all around them others were floundering?

“In one sense we didn’t have massive contracts to lose,” says Karen.

“Also Declan and Brendan were and still are very pro-active and are constantly giving their input. Brendan runs production so he is down on the floor every single day. It goes a long way towards the ethos of the company that the management is constantly involved.”

On its books today Irish Pressings counts household names like Honda, Rolls Royce, BMW, Nissan to name but a few. The parts they supply range from relatively small to upwards of a meter in length.

Declan Ward receiving an award on behalf of Irish Pressings at Honda’s 2017 Supplier Convention.

And while it remains focused on growing its customer base, it would also like to enhance its employee base by another ten to 15 workers.

With so many young people leaving for sunnier climes like Australia or Canada, recruitment is not straightforward.

“The younger generations are not focussed on engineering,” says Declan. “It is all about computers and about getting to college or university.”

A lack of engineering courses in the west of Donegal is not helping their cause either.

“We use specialist machinery and you don’t have the courses in this side of the county for it. So we are focussing on training people in-house. They can come in here and we can train them in tool making,” Karen Campbell added.

With plans to expand its work and grow its customer base, the future looks extremely bright for Irish Pressings. In fact as recently as November last, the company was presented with the ‘Growth Through Export’ Award at the Letterkenny Business Awards.

Eimear Boyle, Karen Campbell, Declan Ward and Sarah Mulholland, all from Irish Pressings, receiving a ‘Growth Through Export’ award at the 2017 Letterkenny Business Awards.

Honda too has recognised the achievements of the firm, presenting Irish Pressings with a Supplier Contribution Award at its 2017 Supplier Convention.

“Myself and Brendan still live in Kincasslagh. That was always part of the plan. When you want to put down roots, what better way than to start your business for yourself and for others,” Declan Ward adds.

“Who says cars have to be produced in Germany or Japan? Why not in Gaoth Dobhair, we are as good as anywhere in the world?”

Posted: 2:00 pm May 18, 2018